Comparing Sheet Metal Joint Sealing Options: Tape vs. Sealing Compounds

When you’re working with sheet metal, whether it’s ductwork, panels, or any other application, the question of how to seal the joints always comes up. It might not be the flashiest part of the job, but it matters. A poor seal can lead to leaks, corrosion, wasted energy, and even safety issues down the road. In Ontario, where temperature swings and humidity can test any installation, the choice of sealing method makes an even bigger difference.

The two most common options are sealing tape and liquid or paste-based compounds. On the surface, they both promise the same thing: a tight, reliable seal. But in practice, they perform quite differently, and the better option depends on the job at hand.

Tape: Quick, Clean, and Familiar

Most sheet metal workers are comfortable with tape. It’s quick to apply, doesn’t require extra tools, and gives you instant coverage. Aluminum foil tape, for example, is a staple in HVAC installations. It sticks well to clean surfaces, holds up under heat, and gives you a finished look that’s easy to inspect.

The downsides? Tape can be unforgiving if the surface isn’t prepped properly. Dust, oil, or even a little moisture will weaken the bond. Over time, especially if the system experiences vibration or big temperature changes, some tapes can peel or lift at the edges. That doesn’t mean tape is a bad option—it just means it needs to be used in the right setting and with the right prep.

Sealing Compounds: Messier but More Durable

Sealing compounds, sometimes called mastics, are a different approach. Instead of laying down a strip, you brush, spray, or trowel the compound directly onto the joint. Once it cures, you’re left with a flexible but strong seal. Good mastics resist cracking, handle pressure changes, and stand up better against long-term vibration.

The trade-off is that compounds are messier and take more time to apply. You’ll need to factor in drying or curing time before moving on, which can slow down a tight schedule. That said, for permanent systems where durability is the top priority—think industrial ductwork or outdoor applications—compounds often outperform tape in the long run.

How to Decide

So which one’s better? The truth is, it depends. If speed and ease of application are your top concerns, tape is hard to beat. It’s especially useful in residential settings or smaller jobs where appearance matters and access is limited. On the other hand, if you’re sealing a system that needs to hold up for decades, or one that will be exposed to extreme conditions, sealing compounds usually pay off in performance and durability.

The best approach might even be a mix. Some contractors apply tape over compound to get the advantages of both strong underlying seal with a neat finished surface.

Bottom Line

Choosing between tape and sealing compounds isn’t about one being right and the other wrong. It’s about the specific job, the environment, and the expectations for performance. In Ontario’s climate, with cold winters and hot, humid summers, the stakes are higher than in milder regions. Taking the time to match the sealing method to the project can save money, energy, and frustration later on.

MORE ARTICLES

Hydronic vs. Forced Air Heating: Pros, Cons, and Ideal Applications

Choosing the right heating system for a residential or commercial project can be challenging, especially when weighing hydronic (radiant) heating against forced air systems. Both have distinct advantages and drawbacks, and the best choice depends on your specific needs.

READ MORE

Hydronic Heating vs. Forced Air Pros and Cons for Cold Climates

Winter in a cold climate can be brutal if your heating system isn’t up to the task. That’s why choosing between hydronic (radiant) heating and forced air matters. Both can keep a house warm, but they do it very differently—and the choice can affect comfort, bills, and even air quality.

READ MORE

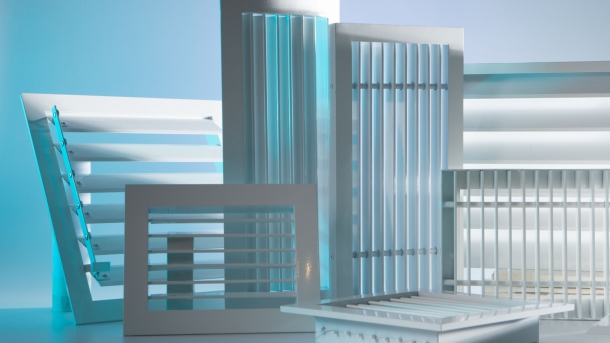

Air Distribution: What Type of Grille or Diffuser is Right for Your Application?

When it comes to air distribution, the grille or diffuser might seem like a finishing touch, but the right selection plays a crucial role in both comfort and system performance. Whether you’re a contractor specifying components for a commercial project or a homeowner updating your HVAC system, understanding the differences between grilles and diffusers helps ensure proper airflow, energy efficiency, and aesthetic integration.

READ MORE